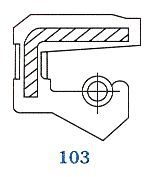

Oil seal A (103) 80x100x12 Viton SOG/TW , ZF 0750111017

-

Code:47080100129

-

Weight:0.000 Kgs

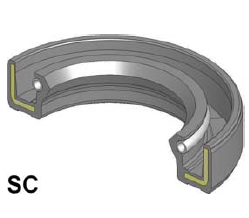

Oil seal type AS (104), without dust lip and with spring.

Material: fluoride rubber ( FPM)

Helix:

OE references: ZF 0750111017

Suitable for:

The nitrile rubber may vary in color from the one shown in the picture, without this affecting the sealing properties of the oil seal.

Manufacturer: SO GIANT OIL SEAL INDUSTRIAL CO., LTD

For delivery options to your country, please do not hesitate to contact us!

Fluororubber properties:

Standard color: brown

Excellent resistance to mineral oils, aliphatic and aromatic hydrocarbons, as well as hydrocarbons containing chlorine, concentrated and dilluted acids, weak alkalis. Its excellent heat resistance (up to +200°C), as well as cold resistance (-30°C), depending on the type of seal, along with its good mechanical properties and remarkable aging resistance, place fluororubber well above the traditional synthetic rubbers. It is especially suitable for high peripheral velocity applications.

Advantages:

- excellent heat resistance within a wide temperature range: from -30°С to 200 °С

- superior resistance to oil and fuels as compared to other rubber types

- the only highly elastic rubber which is resistant to aromatic and chlorinated hydrocarbons

- negligible gas permeability

- excellent weather and ozone resistance

- excellent acid resistance to both concentrated and dilluted acids

- good resistance to weak alkalis

- low swelling in water

Limitations:

- limited flexibility in cold conditions

- limited tensile and tear strength

- limited wear resistance

- high compression set in hot water

- poor resistance to polar solvents