Hydraulic rod seal RS 36х46.7х4.2 PU98 + NBR70 до 350 bar KVK/China

-

Code:33036046042

-

Weight:0.020 Kgs

Product data

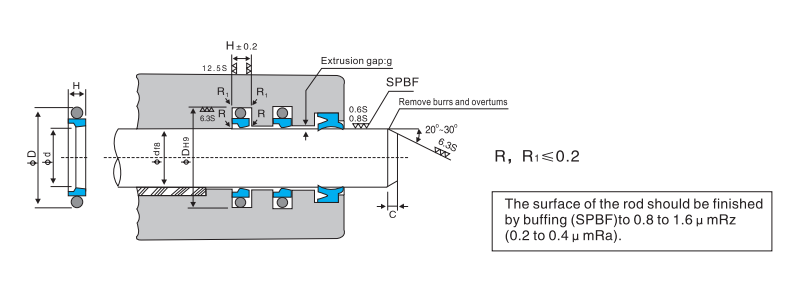

Ød=36 mm ; ØD=46.7 mm ; H=4.2mm ; R1 max:0.4 mm ; O-ring: 41.2x3.55 mm

Material: PU98+NBR70

Application range (the following limit values cannot appear at the same time):

Pressure: ≤ 350 bar

Speed: ≤ 4.0 m/s

Temperature: -35°C ~ +180°C

Media: mineral hydraulic oils, water-glycol hydraulic oils, emulsions

Manufacturer:

Zhongxingshun Sealing Products Factory

Estimated Shipping

to Targovishte starts at

€6.08

outside Targovishte starts at

€6.28

to Targovishte starts at

€6.08

outside Targovishte starts at

€6.28

outside Targovishte starts at

€6.04

to Targovishte starts at

€6.04

outside Targovishte starts at

€6.04

to Targovishte starts at

€6.04

The RS-PU type piston rod seal consists of a PU piston rod seal ring and an O-ring, used to seal the piston rod and piston of a hydraulic cylinder. The use of specially modified PU material can provide excellent low friction, wear resistance, pressure resistance, high temperature resistance and chemical corrosion resistance. The use of O-rings of different materials ensures a wide operating temperature range. Due to the special shape design, it has good oil film return characteristics. The RS-PU type is especially suitable for control cylinders, servo systems, machine tools, fast-response cylinders and construction machinery.

Applications:

Working pressure: ≤35MPa

Working temperature: -30℃~+180℃ (depending on the O-ring material)

Reciprocating speed: ≤4m/s

Media:

General petroleum-based hydraulic oil, water-glycol hydraulic oil, oil-water emulsion hydraulic oil.

Installation:

Rod diameter below 30mm requires open grooves to avoid damage to the sealing edge, measures should be taken to avoid sharp edges during installation.

Material:

Modified PU , high-performance NBR or FPM with different hardness, the standard type is high-performance NBR with hardness 70 degrees.

The main advantages are:

Particularly strong wear resistance.

Insensitive to shock loads and pressure peaks.

High crush resistance.

Ideal forehead density under no-load and low temperature conditions

Sealing effect.

For the toughest working conditions.