Hydraulic rod seal RS 48х58.7х4.2 PTFE+bronze/NBR70 KVK до 400 bar KVK/Chin

-

Code:33048058043

-

Weight:0.020 Kgs

Product data

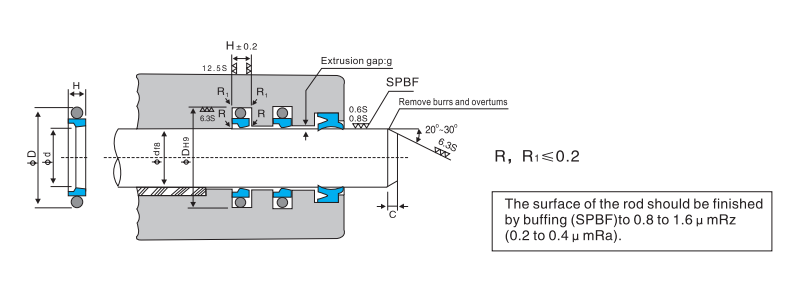

Ød=48 mm ; ØD=58.7 mm ; H=4.2mm ; R1 max:1.2 mm ; O-ring: 53x3.55 mm

Material: PTFE+bronze/NBR70

Application range (the following limit values cannot appear at the same time):

Pressure: ≤ 400 bar

Speed: ≤ 4.0 m/s

Temperature: -35°C ~ +180°C

Media: mineral hydraulic oils, water-glycol hydraulic oils, emulsions

Manufacturer:

Zhongxingshun Sealing Products Factory

Estimated Shipping

to Targovishte starts at

€6.08

outside Targovishte starts at

€6.28

to Targovishte starts at

€6.08

outside Targovishte starts at

€6.28

outside Targovishte starts at

€6.04

to Targovishte starts at

€6.04

outside Targovishte starts at

€6.04

to Targovishte starts at

€6.04

The RS type piston rod seal consists of a PTFE piston rod seal ring and an O-ring, used to seal the piston rod and piston of a hydraulic cylinder. The use of specially modified PTFE material can provide excellent low friction, wear resistance, pressure resistance, high temperature resistance and chemical corrosion resistance. The use of O-rings of different materials ensures a wide operating temperature range. Due to the special shape design, it has good oil film return characteristics. The RS type is especially suitable for control cylinders, servo systems, machine tools, fast-response cylinders and construction machinery.

Applications:

Working pressure: ≤40MPa

Working temperature: -30℃~+180℃ (depending on the O-ring material)

Reciprocating speed: ≤4m/s

Media:

General petroleum-based hydraulic oil, water-glycol hydraulic oil, oil-water emulsion hydraulic oil.

Installation:

Rod diameter below 30mm requires open grooves to avoid damage to the sealing edge, measures should be taken to avoid sharp edges during installation.

Material:

Modified PTFE+bronze, high-performance NBR or FPM with different hardness, the standard type is high-performance NBR with hardness 70 degrees.

The main advantages are:

Particularly strong wear resistance.

Insensitive to shock loads and pressure peaks.

High crush resistance.

Ideal forehead density under no-load and low temperature conditions

Sealing effect.

For the toughest working conditions.